- Home

- About

- Courses

- IR/INFO CONFERENCE

- Software

- EXPERT SERVICES

- STANDARDS

- Proposal Templates

- Electrical Systems & Rotating Equipment

- Building Envelopes

- Insulated Roofs

- Photovoltaic Systems

- Pest Detection

- Yachts and Small Craft

- Thermal Imaging of Horses

- Optical Gas Imaging

- Measuring Reflected Temperature

- Measuring Emittance

- Measuring Transmittance

- Distance/Target Size Ratios

- Complete Series

- Resources

- BUSINESS OPPORTUNITIES

- STORE

Volume 6 Issue 6 June 2017

Director’s Message

Whether you work as a professional thermographer or are setting up an in-house infrared inspection program, it is important to accurately represent the benefits of thermography to prospects or peers. Failure to do so can lead to unrealistic expectations and disappointment.

The statement, ‘Thermography saves time and money’ is a popular phrase associated with our technology; however, it is a fallacy. As a practice, thermography alone saves neither time nor money. This is due to the fact that infrared inspections require time for their planning and execution, both of which come with a cost. Furthermore, correcting detected exceptions will require additional time and money.

The statement, ‘Thermography saves time and money’ is a popular phrase associated with our technology; however, it is a fallacy. As a practice, thermography alone saves neither time nor money. This is due to the fact that infrared inspections require time for their planning and execution, both of which come with a cost. Furthermore, correcting detected exceptions will require additional time and money.

When listing the benefits of thermography, it is important to accurately represent the benefits of the technology in order that others may set their expectations appropriately. This is especially important when seeking approval for in-house programs in order that they may be appropriately funded and staffed.

To this end, an alternative to the aforementioned statement might be:

Combined with timely, effective repairs, thermography can help to save time and money by reducing unscheduled downtime or premature failures.

To this end, an alternative to the aforementioned statement might be:

Combined with timely, effective repairs, thermography can help to save time and money by reducing unscheduled downtime or premature failures.

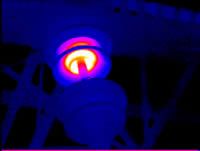

Using Tmax Corrected to Prioritize Electrical Exceptions

Thermographers have long used temperature differentials or Delta T measurements as a means of prioritizing electrical and mechanical exceptions. Typically, Delta T values are calculated by comparing the temperature of an exception to similar components under similar load or to ambient air temperature. Although they work well in many circumstances, Delta T readings are not applicable for components that do not qualitatively manifest themselves as an exception.

An alternative to Delta T calculations is a formula known as Tmax Corrected. This formula is based upon an IEEE formula and calculates pass/fail criteria based upon several factors including equipment type, ambient air temperature, and circuit load.

Despite taking a little more time to apply than Delta T calculations, Tmax Corrected allows one to determine if a component of interest is running within specification for any load or ambient temperature. Tmax Corrected is especially useful for equipment that is not manifesting itself as an exception. Tmax Corrected can be an invaluable tool for those who perform infrared inspections as part of commissioning studies or use thermography for acceptance testing of new installations, repairs, or retrofits.

Proper use of the Tmax Corrected formula is just one of the many topics covered in Infraspection Institute’s Level II training courses. The proper application of Tmax Corrected may also be found in the Standard for Infrared Inspection of Electrical Systems and Rotating Equipment.

Despite taking a little more time to apply than Delta T calculations, Tmax Corrected allows one to determine if a component of interest is running within specification for any load or ambient temperature. Tmax Corrected is especially useful for equipment that is not manifesting itself as an exception. Tmax Corrected can be an invaluable tool for those who perform infrared inspections as part of commissioning studies or use thermography for acceptance testing of new installations, repairs, or retrofits.

Proper use of the Tmax Corrected formula is just one of the many topics covered in Infraspection Institute’s Level II training courses. The proper application of Tmax Corrected may also be found in the Standard for Infrared Inspection of Electrical Systems and Rotating Equipment.

Infraspection Proposal Templates

For professional thermographers, the first step in approaching any new project should be to generate a formal proposal. This proposal should contain all information pertinent to the project and be sufficiently detailed to reflect the responsibilities of all parties including the client and the thermographer.

Infraspection Institute offers standard proposal templates for several different types of residential and commercial infrared inspections. Each template provides suggested wording and format for preparing a comprehensive and professional proposal.

Nine proposal templates are currently available covering the following applications: electrical systems, mechanical systems, electro/mechanical systems, photovoltaic systems, building envelopes, insulated roofs, process equipment, steam traps, and underground piping. Each template outlines scope of work, pricing options, client and thermographer responsibilities, applicable standards, additional services, and terms.

Infraspection Institute offers standard proposal templates for several different types of residential and commercial infrared inspections. Each template provides suggested wording and format for preparing a comprehensive and professional proposal.

Nine proposal templates are currently available covering the following applications: electrical systems, mechanical systems, electro/mechanical systems, photovoltaic systems, building envelopes, insulated roofs, process equipment, steam traps, and underground piping. Each template outlines scope of work, pricing options, client and thermographer responsibilities, applicable standards, additional services, and terms.

All templates are provided in a Microsoft Word file and can be modified to suit the user’s particular needs. Templates may be used as core language for contract documents. Purchase price includes license for unlimited use of the template by the original purchaser. Templates are available individually or as a complete set of nine.

Call for Papers for IR/INFO 2018

Infraspection Institute are pleased to announce that our annual Advanced Training Conference, Technical Symposium and Technology Expo, IR/INFO 2018, will be held January 21 – 24, 2018 in New Orleans, Louisiana. Now in its 29th year, IR/INFO features four days of networking, learning, and fun in a relaxed, yet professional, family atmosphere.

We are presently seeking papers and presenters for IR/INFO 2018. Invited topics include, but are not limited to: safety, emerging applications, building sciences, related NDT, case histories, as well as tips and tricks.

We are presently seeking papers and presenters for IR/INFO 2018. Invited topics include, but are not limited to: safety, emerging applications, building sciences, related NDT, case histories, as well as tips and tricks.

Presentations are typically 20-25 minutes with 5 minutes for Q & A time with the audience. All papers and presentations will be published in the IR/INFO Proceedings. The deadline for abstract submissions is July 31.

Professional Curriculum

Infraspection Institute instructors use extraordinary techniques to deliver stimulating, effective, and relevant instruction. All of our instructors are highly experienced, practicing thermographers. Each brings years of unmatched, real-world experience to the classroom. Our courses are taught using a combination of dynamic multi-media presentations, hands-on demonstrations and one-on-one interaction with students. Our courses integrate theory, practice, and case studies in a fun, relaxed atmosphere designed to maximize your learning experience.